Our production

Advantages of flexo printing

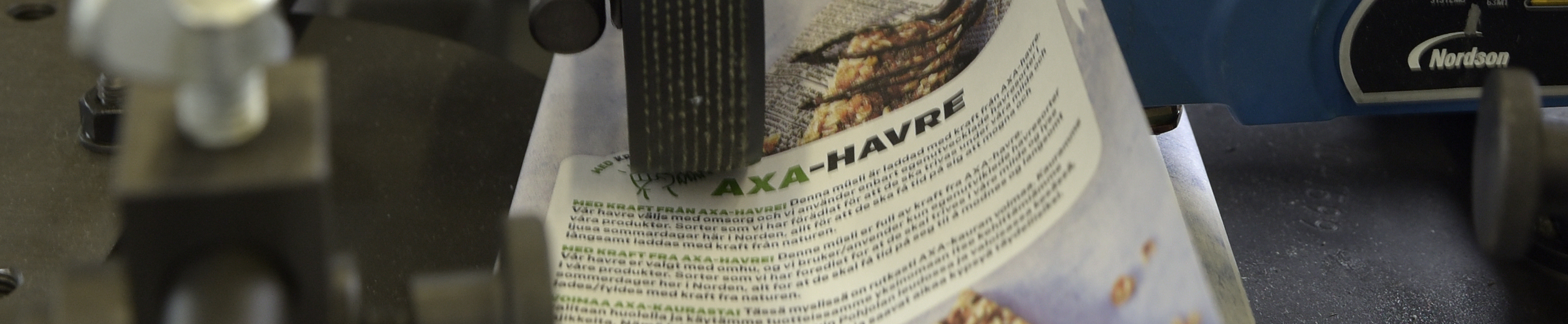

Flexo printing is an increasingly common printing method, when it comes to different types of packaging. The method is economically advantageous, as it offers greater flexibility than traditional depth printing. This is especially true when printing shorter series, as flexotry gives shorter turnaround times and lower boot costs.

The technical development has meant that flexotry now meets high demands on quality, including multi-color printing and photographic reproduction.

customer needs

Converflex printing processes are continuously evolving based on new technological capabilities and the growing demand for fast switches for time-limited campaigns and activities. In the huge range of goods it is of the utmost importance to be seen on the shelves and to stand out in the crowd.

Converflex’s priorities and investments are largely controlled based on these customer needs. In close consultation with customers and end users, new solutions are constantly being developed, which further enhance the quality and increase the efficiency of the printing process. And as such, it also increases customer competitiveness in the market. What appears sells.

BEST IN THE INDUSTRY

Today, Converflex’s printing is in print on two printing presses, an 8-color and a 10-color. In 2012, a new 10-color printing press was installed, which further improved capacity and quality. Converflex AB is “HD-Flexo” certified. This means that you belong to the best in the industry, for example development and range of flex quality.

Our machines

Printing machines

The printing machines peripheral equipment is designed for decorators with up to 10 colors. The machines can handle a width of 1.5 meters and the rolls can have a diameter of 1.5 meters.

Converflex AB strives to adapt production flow to avoid unnecessary items. Customers’ desired size of the rollers is customized directly in the printing presses, which are also adapted for fast changing between the 1000’s of decorators handled in production. The colors used are water based to avoid unnecessary environmental impact while achieving the best printing results.

With the instruments and equipment available to Converflex AB, you can measure and make recipes for all color shades, adapted to the material to be printed.

Bag machines

Converflex AB both production lines for bags are adapted for different types of paper as well as paper with barrier (such as PE plastic).

Examples of bags are flour, oatmeal, muesli, potatoes, picking sweets and fruit.

Pictures from our production

📍 Find us

Outside Örnsköldsvik you will find our business. Welcome!